5 Benefits of Using a Custom Woven Wire Mesh

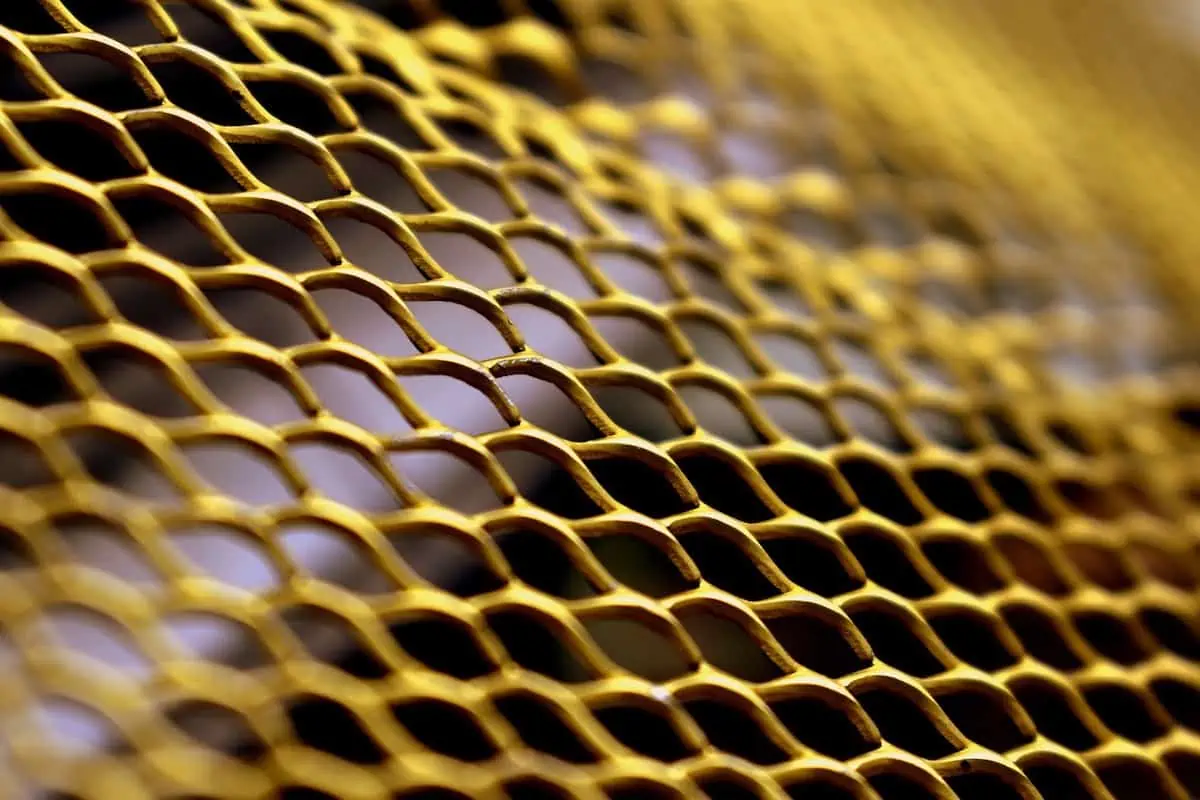

Woven wire mesh is a versatile material used in many industries, including construction, manufacturing, and security. It is made by interweaving metal wires to form a grid-like pattern. Custom woven wire mesh offers the ability to tailor the material to specific needs, making it an even more useful option for various applications.

In this article, we will discuss five key benefits of using custom woven wire mesh. These benefits can help businesses and individuals get the most out of this versatile material.

Table of Contents

1. Tailored to Specific Requirements

One of the main benefits of custom woven wire mesh is that it can be designed to meet specific needs. Whether you need a particular size, pattern, or wire thickness, custom meshes can be manufactured to your exact specifications.

This is especially useful when standard mesh products don’t fit your project requirements. For example, industries like agriculture, construction, and filtration can benefit from meshes made for particular purposes, ensuring that the final product performs as needed.

2. Enhanced Durability and Strength

Custom woven wire mesh is often stronger and more durable than other types of mesh. The weaving process creates a solid structure that can withstand heavy loads, high pressure, and even extreme weather conditions.

This makes it ideal for applications where strength is a priority, such as fencing, safety barriers, or reinforcing concrete. Since the wire is tightly woven, it resists breaking and is less likely to deform under stress, ensuring that your mesh will last longer and perform better.

3. Versatility in Use

A custom Woven Wire mesh is incredibly versatile. It can be used for a variety of purposes, from creating decorative elements to providing security. In construction, it can be used for reinforcing concrete, while in agriculture, it can be used for creating protective fencing.

Additionally, custom woven wire mesh is commonly used in the automotive industry for things like exhaust systems or filters. This versatility makes it a go-to material for many different projects, ensuring that you get exactly what you need for your specific application.

4. Improved Aesthetic Appeal

While woven wire mesh is often used for practical purposes, it can also add a unique aesthetic touch to a design. Custom woven wire mesh can be designed in various patterns and colors, allowing it to fit seamlessly with the overall look of a project.

For instance, it can be used in architecture to create decorative facades, modern screens, or even as an element in interior design. The ability to customize the appearance of the mesh helps to improve the visual appeal of a space while still maintaining its functional benefits.

5. Cost-Effective Solution

Another benefit of custom woven wire mesh is that it can be a cost-effective solution for many projects. While there might be an initial investment in creating a custom mesh, the long-term benefits often outweigh the costs.

The durability and strength of the mesh mean that it will need to be replaced less frequently, saving you money over time. Additionally, since you can order the exact size and design needed, there is less waste, which can also lead to cost savings.

Conclusion

Custom woven wire mesh offers numerous advantages that can make a big difference in the success of a project. From being tailored to your specific needs to providing strength and durability, it is an excellent choice for a variety of applications.

Whether you are using it for security, construction, or even design, custom woven wire mesh can help you achieve the perfect result.